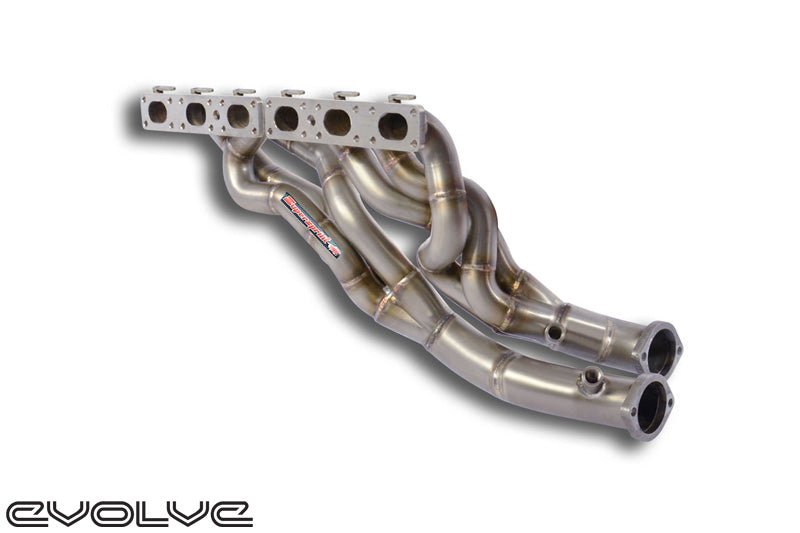

A good header design is key to unlocking performance gains from naturally aspirated motors. At Supersprint every header is designed, developed and manufactured within our factory here in Mantova, Italy.

With performance gains the main objective, we study and design primary and secondary piping configurations with varying diameters and lengths. These are then tested on our in-house MAHA Dynamometer enabling us to recognise the optimum setup. We also ensure the 02 sensor bungs remain in their original position for ideal fitting.

Supersprint headers are manufactured using industry leading techniques from the best German 304 and 310S stainless steel with piping thickness variable from 1 to 1.5mm, along with CNC machined, hi-precision laser cut flanges built from 409 and 304 steel for perfect fitment and longevity. Our joints are TIG welded in order to guarantee strength and durability. For temperature critical, delicate applications we also use Inconel for some of our products.

These materials and processes ensure Supersprint headers are extremely high quality, durable products that offer true, tangible performance gains.